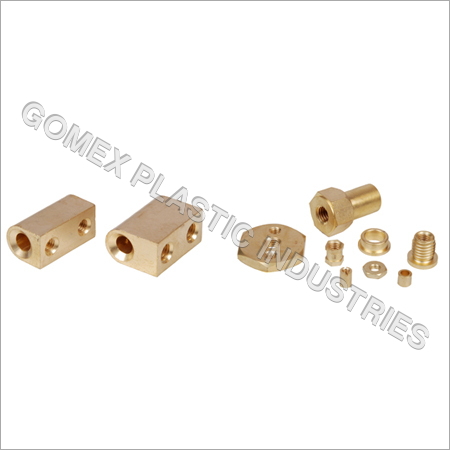

Brass Turning Parts

MOQ : 10000 Pieces

Brass Turning Parts Specification

- Product Type

- Brass Turning Parts

- Material

- Brass

- Thickness

- Customized as per requirement

- Surface Treatment

- Polished / Plain / As per requirement

- Finishing

- Smooth Finish

- Size

- Standard & Custom Sizes Available

- Color

- Golden

- Processing Technique

- CNC Turning, Precision Machining

- Tolerance

- ±0.01 mm or as specified

- Hardness

- Soft, Half Hard, Hard as per requirement

- Thread Type

- Metric, UNC, UNF, BSP, BSW or as required

- Grade

- IS 319 / BS 249 / As per customer specification

- Head Shape

- Round, Hex, Custom shapes available

- Usage

- Machinery, Electrical, Electronics, Automotive applications

- Packaging Type

- Poly Bag, Carton, Wooden Box

- Corrosion Resistance

- High

About Brass Turning Parts

Owing to the huge demand of our clients, we are able to manufacture, supply and export a wide range of Brass Turning Parts. Made of high quality brass that is supposed to be the best in the market, these products do not falter at time of operation. These products are duly checked by our team of skilled and trained quality controllers to ensure their supreme quality. Keeping in mind the variegated needs of the clients, we offer these products in different specifications. Brass Turning Parts are packed in special packaging material to ensure their safe and secure transit.

Features:

- Relative resistance against tarnishing

- High durability

- Correct dimensions

- Easy fitting

- Excellent finish

Range:

Brass earth link, earth bar, neutral bar,brass neutrallink, brass earthlink, brass cablegland, brass turned components, brass samitary fittings, brass article, brass audio video acc., brass anchor, brass electrical wiring acc., brass hrc fuse parts, brass switchgear parts, brass neutro, brass terminal, brass pcb terminal, brass mcb terminals,

brass components, brass parts, brass turned parts, brass hrc fuse parts, brass terminal, bus bar supporter, brass neuter link, brass earthlink, brass earthbar, brass neutralbar, neutral link, neutral links, earth bar, brass neuterlink, copper bus bar supporter,brass cable gland, cable glands, copper bus bar supporter, bus bar supporter, brass conduit fittings, brass cable gland,brass terminals, brass terminal strip, brss strip.

Brass Turning Parts can be developed and supplied exactly as per customer drawings, design, specifications, samples & requirement.

Material : Free cutting brass

High grade free cutting brass

Any Special Brass Material Composition As Per Customers Requirement

Sizes : As per customer drawings & specification or samples.

Finish : Natural, Nickel Plated, Tin Plated or any coating as per customer specification

Precision Manufacturing for Reliability

Our brass turning parts undergo CNC turning and precision machining, achieving an exacting tolerance of 0.01 mm. This meticulous process ensures consistent quality and dimensional accuracy, making them ideal for critical machinery and electronic assemblies requiring dependable performance.

Versatile Application Across Industries

These brass components are designed to serve a wide array of sectors, from electrical and electronics to automotive and general machinery. Their adaptability stems from the availability of multiple thread types, head shapes, and grade options, facilitating use in diverse operational environments.

Customizable Features for Unique Requirements

Customers can specify thickness, hardness, finishing, and packaging to suit their exact needs. With options ranging from soft to hard hardness, polished or plain surface treatments, and a choice between standard or custom sizes, these parts can be tailored for optimum fit and function.

FAQs of Brass Turning Parts:

Q: How are brass turning parts manufactured to ensure precision?

A: Brass turning parts are produced using CNC turning and precision machining processes, which provide tight tolerances of 0.01 mm or as specified. This guarantees accurate dimensions and high-quality finishing, suitable for demanding industrial applications.Q: What types of threads and shapes are available for these components?

A: Various thread types such as Metric, UNC, UNF, BSP, and BSW are offered along with head shapes including round, hex, and custom configurations. This allows the parts to seamlessly integrate with different machinery and assemblies.Q: When should I specify custom grading or hardness?

A: Custom grading (IS 319, BS 249, or per requirement) and hardness (soft, half hard, hard) should be specified when your application demands particular mechanical properties, ensuring the parts deliver optimal performance in specialized environments.Q: Where are these brass turning parts commonly used?

A: They are widely utilized in machinery, electrical devices, electronics, and automotive applications due to their excellent corrosion resistance, mechanical strength, and adaptability to various designs and operational settings.Q: What is the process for obtaining parts with bespoke specifications?

A: To order parts with custom features such as thickness, finish, or packaging, clients simply provide their specific requirements during quotation. The manufacturer then tailors each aspect, including material grade and surface treatment, to match client needs.Q: What are the benefits of choosing brass turning parts from an Indian exporter, manufacturer, or supplier?

A: Indian exporters and manufacturers offer globally competitive pricing, high-quality materials, and flexible customization. Their experience in international supply guarantees prompt delivery and reliable after-sales support.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS